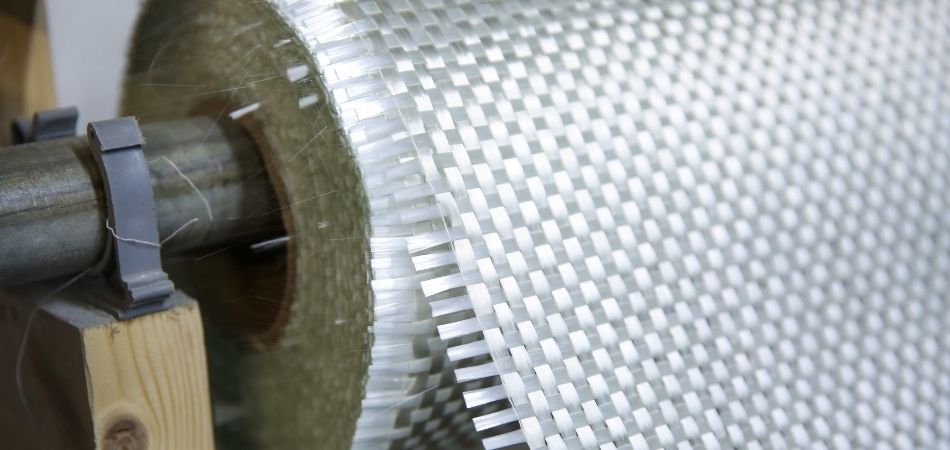

Why is your outdoor enclosure cracking after six months? Or why did that prototype shatter when dropped from a workbench? If you’re asking these questions, you’re likely battling the “Triangle of Trade-offs” in thermoplastic selection: Cost, Toughness, and Weatherability. At BLG Fiberglass, we see this constantly in our vacuum forming projects. You want the price […]

Main Services

Value-Added Services

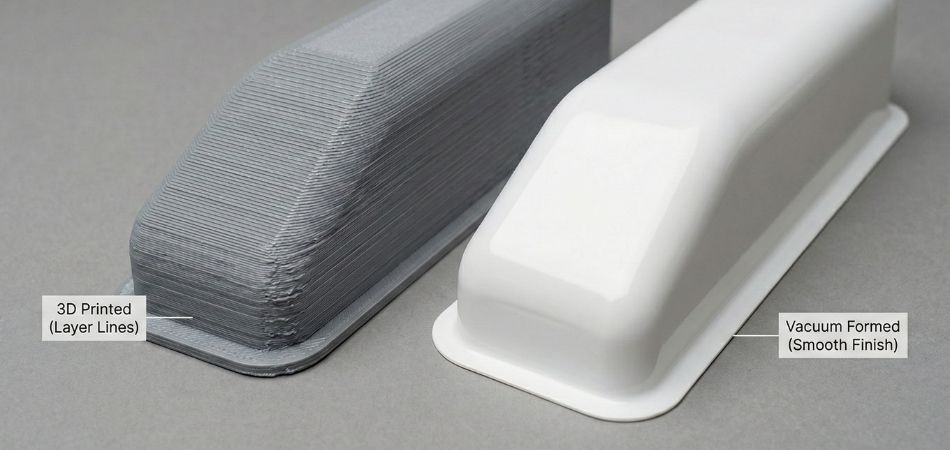

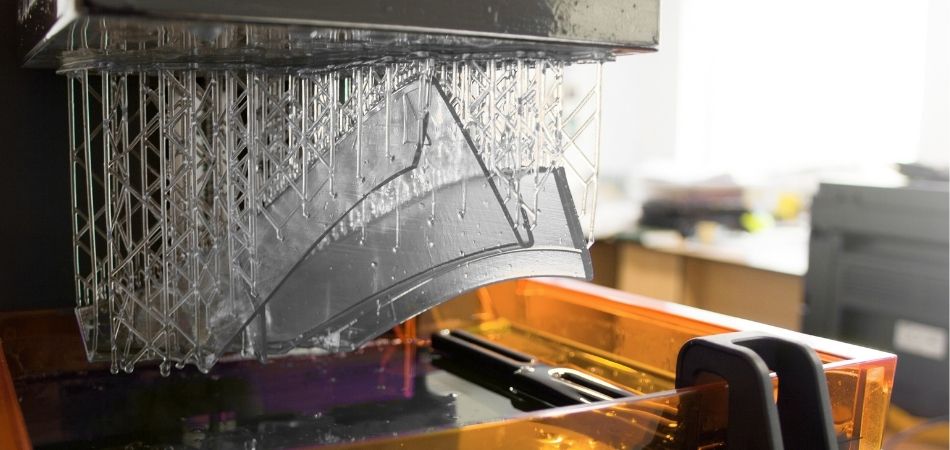

Pattern Development (3D Digitization)

Mold Creation (CNC Machine Creates Master/Pattern)

Painting (Primer/Top)

Secondary Component Installation (PVC, Metal, Wood, and Rubber)