Main Services

Value-Added Services

Pattern Development (3D Digitization)

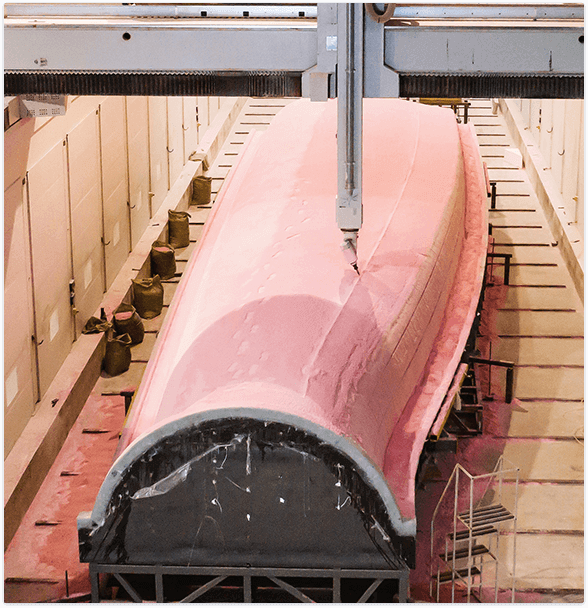

Mold Creation (CNC Machine Creates Master/Pattern)

Painting (Primer/Top)

Secondary Component Installation (PVC, Metal, Wood, and Rubber)

We are a Canadian-based company founded in 2000. We have more than 50,000 square metres of office space and manufacturing facility in Shanghai and Jiangsu China with more locations in Canada and the US. Our focus has always been to make the best fiberglass products and commit to implementing ideal solutions while offering the customer the highest standard of service, product selection, quality, and value.

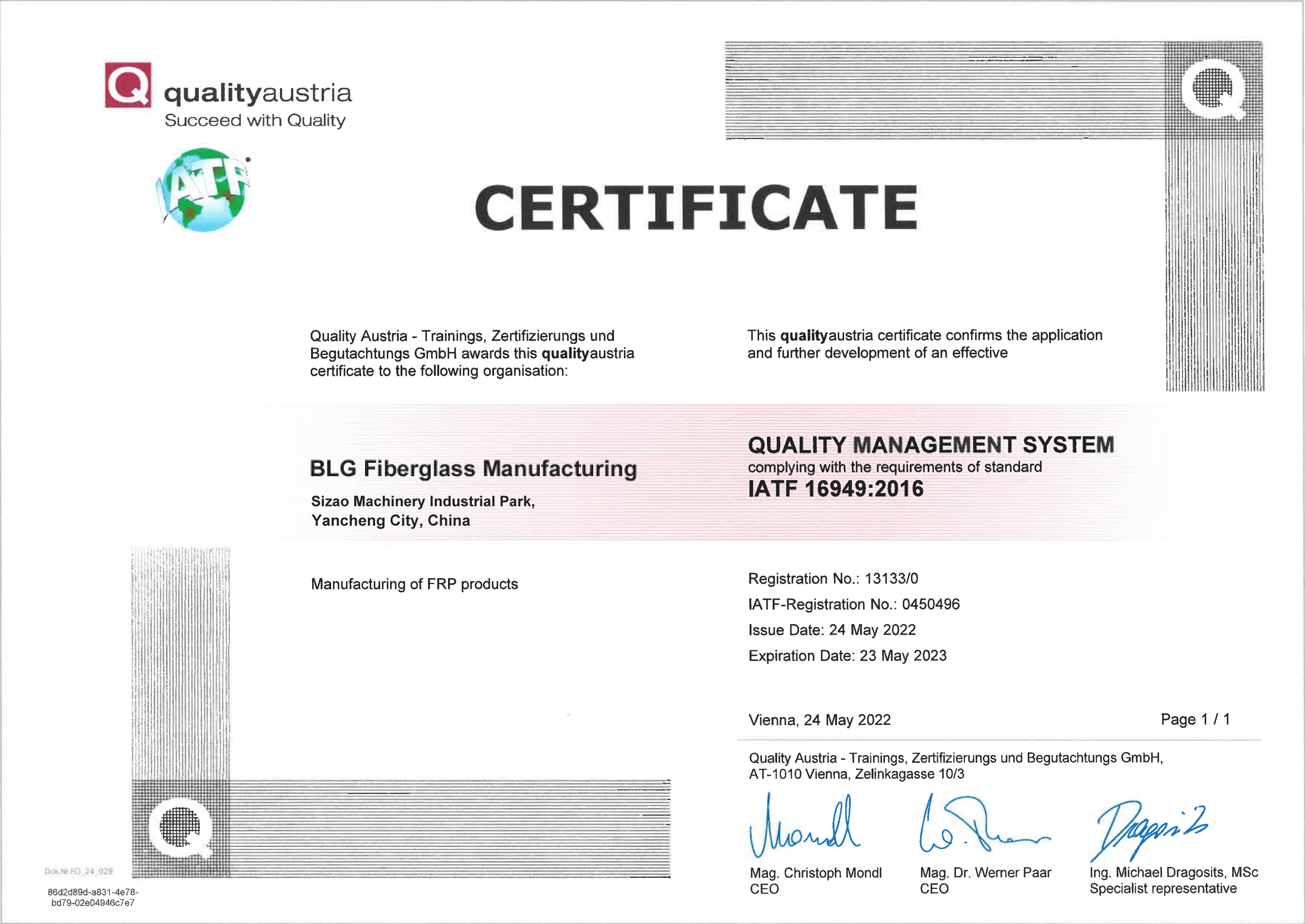

With more than 20 years of experience in the industry, we can provide clients with high-standard finished fiberglass products and advanced engineering solutions. With ISO9001 and government-provided manufacturing certification, we have supplied more than 10 million parts to the clients in transportation, wind turbines, medical, and marine industries all over the world. Our professional team analyzes your product specifications, part manufacturability, program budget and annualized volume requirements to establish a mold tooling and production fixture plan/package. To support your needs from concept to reality, we assist in coordinating the design and pattern development phases of the mold tooling project. This will be done prior to leading the building and validation of the production molds and fixtures.

At BLG, we work hard to provide our clients with more than just components for their vehicles, boats, pipes, storage tanks, CT machines, and more. With every project we take on, we are guided by the following values:

Promote a positive experience with every client that we work with.

Maintain reliable, trustworthy, honest, ethical and respectful partnerships

Continue to pursue innovative technology that is more reliable and green.

BLG maintains the highest standards of quality when it comes to the development of our parts and manufacturing processes.

We are proud to announce that we have IATF 16949 certification and follow the IATF 16949 technical specifications to continuously improve and reduce waste in our automotive industry supply chain and assembly process.

We always work to code, and get things done the right way. To learn more about how we can provide sustainable and responsibly manufactured FRP products, contact us today!

Our company has developed strong working relationships with companies from so many industries because of our commitment to delivering high-quality components.

If you are looking to get a quote on your project or you need more information about our team and services, we encourage you to get in touch with us today. We look forward to hearing from you.