Main Services

Value-Added Services

Pattern Development (3D Digitization)

Mold Creation (CNC Machine Creates Master/Pattern)

Painting (Primer/Top)

Secondary Component Installation (PVC, Metal, Wood, and Rubber)

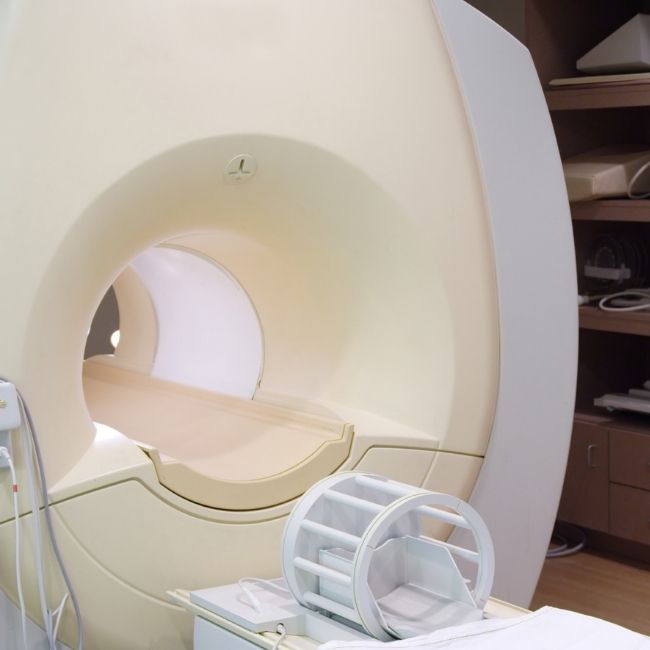

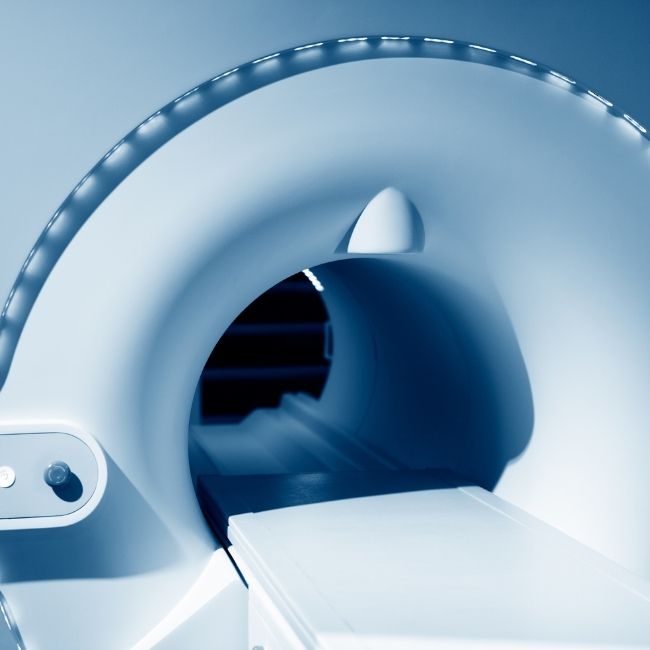

Here at BLG, we have been providing components for imaging equipment for many years now. Those is the medical industry rely on CT and MRI machines to assist them in providing life-changing services, which is why they need reliable parts for their machines.

The experts at BLG Fiberglass have the experience, knowledge and skills to design and construct the materials you need.

We always deliver incredible results. This is part of our efforts to provide our clients with materials that satisfy their needs.

Pattern development, mold creation, painting, secondary component installation, and boding services to serve all your needs.

Our people have many years of experience with producing fiberglass components for the medical industry. We understand the importance of the components we create, which is why we take the time and care to get it right every time for our clients.

Clients know they can count on our people for:

Components designed to their exact specifications

Components made from quality materials

Skilled and professional technicians

Regular updates on their projects

Prompt and timely results

Our company produces components for CT and MRI machines. As an integral part of medical care, these MRI and CT machines are relied on daily. Medical professionals need these machines to perform so that they can give their patients the care they need.

Our company understands this, and that is why we work closely with our clients to better understand their needs and ensure that they get the component and parts that they need. With our experience, we know how to produce top-quality fiberglass components that our clients need. We do this so that our clients in the medical industry can focus on their patients without having to worry about the components in their machines.

There are many benefits of using fiberglass for medical purposes. It is a very strong and durable material that is also very lightweight. This makes it ideal for use in many different medical applications. Fiberglass is also non-conductive, which makes it perfect for use in X-ray and other imaging procedures. It is also hypoallergenic, so it is safe for use with patients who have allergies or sensitivities. Additionally, fiberglass is easy to clean and sterilize, so it can be used in operating rooms and other sterile environments.

Many types of medical devices can be made with fiberglass. Some examples include casts for broken bones, splints for unstable fractures, and orthotics for treating deformities. Fiberglass is also sometimes used to make artificial limbs and dental braces.

The benefits of using fiberglass in medical devices are that it is lightweight, strong, and durable. It can also be easily molded into a variety of shapes, which makes it a versatile material for many different applications.

There are a few ways to fabricate medical devices from fiberglass. One way is to create a mold of the device that needs to be created, and then lay the fiberglass cloth over top of the mold. The cloth is then saturated with resin, and using pressure and heat, the resin cures and sets, creating a replica of the mold in fiberglass.

Another method is to create a gel out of epoxy resin that can be injected into a mold. The fiberglass fibers are then added to the epoxy gel, and the mixture is allowed to cure. This creates a thicker device that can be more durable than devices created through the first method.

Expertise in medical device manufacturing is critical when fabricating fiberglass medical devices. In addition to the usual quality and safety requirements, special attention must be paid to the biocompatibility of the materials used in order to ensure that they do not cause adverse reactions in the body.

Manufacturing fiberglass medical devices also requires a high degree of precision and accuracy, as even small variations can have a significant impact on the final product. It is therefore important to select a manufacturer with a proven track record of producing quality medical devices.

There are a few different sterilization methods that can be used on fiberglass medical devices, but the most common is autoclaving. This involves using steam to kill any bacteria or other contaminants on the surface of the device. Other methods include ethylene oxide sterilization or gamma irradiation, but these are less common. There are certain requirements that must be met in order to properly sterilize a fiberglass medical device, so it’s important to consult with an expert before attempting any of these methods.

BLG is a manufacturer of medical fiberglass products and our head office is located in Toronto at 3080 Yonge Street, Suite 6060, Toronto, ON, M4N 3N1.

Our medical fiberglass products are strong and durable, making them the perfect choice for a variety of applications. We use only the highest quality materials and craftsmanship to ensure that you receive a product you can trust. Our team is passionate about delivering a product that exceeds your expectations.

Fiberglass medical devices are manufactured to meet stringent safety and performance standards. In order to ensure that these devices meet the required standards, manufacturers undergo a rigorous testing and quality assurance process. This process includes ensuring that the devices are made from high-quality materials, are safe for use in the human body, and perform as intended. Fiberglass medical devices have been used safely and effectively for many years, and continue to be a popular choice for patients and healthcare providers alike. Thanks for your question!

Our company has developed strong working relationships with companies from so many industries because of our commitment to delivering high-quality components.

If you are looking to get a quote on your project or you need more information about our team and services, we encourage you to get in touch with us today. We look forward to hearing from you.