Fiberglass is one of those materials that works behind the scenes in everyday life – found in everything from cars and boats to medical devices and industrial machinery. But here’s the thing: not all fiberglass is created equal. Each type has its own unique properties, and choosing the right one can make a big difference in strength, durability, cost, and overall performance.

In this guide, we’ll walk you through the main types of fiberglass, what sets each one apart, where they’re most commonly used, and which industries depend on them the most.

1. Chopped Strand Mat (CSM)

Chopped Strand Mat is made of short fiberglass strands randomly oriented and held together with a binder. Combined with resin, it forms a solid, lightweight laminate that is easy to work with. Depending on your application, it’s important to ensure your fiberglass materials meet local standards and regulations, such as those for fibre-reinforced polymers in Canada

Why choose CSM:

It’s great when you need strength distributed evenly in multiple directions without the complexity of woven fibers. Its versatility and affordability make it suitable for both DIY and commercial projects.

Benefits:

- Builds thickness for hulls, tanks, and panels

- Resistant to corrosion and chemicals

- Easy to mold and shape with hand lay-up or spray-up methods

Applications:

- Boat hulls and decks

- Automotive panels for low to medium volume production

- Storage tanks and industrial containers

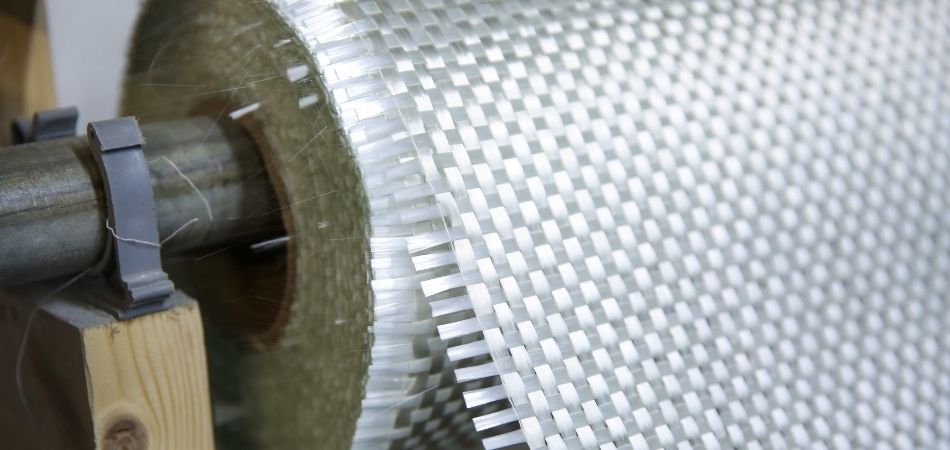

2. Woven Roving

Woven Roving consists of continuous fiberglass strands woven into sheets, providing high tensile strength along the fiber directions. It is often combined with CSM for added structural reinforcement.

Why choose Woven Roving:

Ideal for projects that require high strength in specific directions. It reduces resin usage while maximizing the strength of the final part.

Benefits:

- Superior directional strength for load-bearing areas

- Efficient material use, lowering costs without sacrificing performance

- Works well with other fiberglass types for layered laminates

Applications:

- Structural components in boats, vehicles, and machinery

- Industrial panels and frames requiring targeted reinforcement

- Reinforcement layers in composite laminates

3. Fiberglass Cloth

Fiberglass Cloth is made from finely woven threads forming smooth, uniform layers. It is used where both strength and surface finish matter.

Why choose Fiberglass Cloth:

- Smooth, clean finish for visible surfaces

- Maintains structural support

- Lightweight and flexible for complex molds

Applications:

- Decorative panels and architectural elements

- Automotive and marine finishing layers

- High-quality molded parts like dashboards or instrument panels

4. Continuous Strand Mat (CSM) with Chopped Strands

This type combines continuous fibers with chopped strands, giving balanced strength in multiple directions. It’s ideal for projects that need both structural integrity and durability, especially in medium to high-volume production.

Why choose CSM + Chopped Strands:

Best for parts that experience stress from different directions, such as wind turbine blades or automotive panels.In some projects, these fiberglass parts are paired with vacuum-formed plastic components, such as lightweight covers or protective housings. Combining the two materials gives you both strength and precision, making the final assembly stronger, lighter, and more versatile.

Benefits:

- Balanced strength, reducing weak points

- Resistant to cracking, deformation, and impact

- Efficient for medium to high-volume production

Applications:

- Wind turbine blades that resist bending

- Industrial containers and tanks facing repeated stress

- Automotive body panels designed for durability

5. Specialty Fiberglass (E-Glass, S-Glass, C-Glass)

Specialty fiberglass is designed for specific performance needs, including higher strength, chemical resistance, or electrical insulation.

- E-Glass: General-purpose fiberglass for electrical and structural use

- S-Glass: Extra tensile strength for aerospace, defense, and high-performance projects

- C-Glass: Corrosion-resistant for chemical storage and harsh industrial conditions

Why choose Specialty Fiberglass:

When your project demands high performance or must withstand specific environmental challenges, specialty fiberglass provides the optimal balance of strength, weight, and resistance.

Applications:

- Aerospace components

- Chemical storage tanks and pipes

- Sporting goods like surfboards or high-performance bicycles

Comparative Chart: Fiberglass Types and Industry Applications

| Fiberglass Type | Strength | Corrosion Resistance | Finish Quality | Best for Industry |

| Chopped Strand Mat (CSM) | Medium | High | Moderate | Marine, Automotive, Industrial |

| Woven Roving | High (directional) | Medium | Moderate | Marine, Automotive, Industrial |

| Fiberglass Cloth | Medium | Medium | High | Automotive, Marine, Architectural |

| CSM + Chopped Strands | High (multi-directional) | High | Moderate | Automotive, Renewable Energy, Industrial |

| Specialty Fiberglass (E/S/C-Glass) | Very High | Very High | High | Aerospace, Industrial, Specialized Projects |

Trust Us Experts..

At BLG Fiberglass, we know that choosing the right type of fiberglass is key to a successful project. Whether it’s CSM for marine applications, woven roving for structural reinforcement, or specialty fiberglass for high-performance engineering, we help you select the right material and manufacturing method.

With experience across automotive, marine, medical, renewable energy, and industrial industries, we make sure every component meets strict standards for quality, durability, and performance.