Wind energy is one of the cornerstones of all global renewable energy strategies. Modern wind farms efficiently transform natural airflow into electric power, but the usually not-recognized star of the show is the blade of the wind turbine. These blades need to be large, strong, and lightweight, while withstanding extreme environmental conditions. The material making it possible is fiberglass, the now-preferred choice for onshore and offshore wind energy production in the building of blades.

This blog explores the reasons for using fiberglass, manufacturing of blades, performance benefits, and its role in sustainability.

Why Fiberglass is the Material of Choice

Wind turbine blades operate under constant stress and extreme environmental conditions. Selecting the right material is critical for safety, efficiency, and longevity. Fiberglass composites provide several key advantages:

- High strength-to-weight ratio: Fiberglass is strong yet lightweight, allowing blades to rotate efficiently while withstanding high wind forces.

- Durability and corrosion resistance: Fiberglass does not rust or degrade under exposure to rain, UV radiation, or saltwater, making it ideal for both onshore and offshore turbines.

- Design flexibility: The material can be molded into complex aerodynamic profiles that maximize energy capture.

These properties make fiberglass superior to metals, wood composites, or even carbon fiber in most wind turbine applications. Metals tend to be too heavy and prone to fatigue, wood lacks uniform performance, and carbon fiber is expensive and brittle under some conditions.

Manufacturing Fiberglass Wind Turbine Blades

Fiberglass blades are manufactured in a very precise and labor-intensive process. Advanced computer simulations first provide the design for the blade to optimize its performance. These designs are then followed by building blade molds, sometimes more than 80 meters in length.

Key steps in blade manufacturing:

- Design and mold preparation: Engineers simulate airflow, stress, and vibration patterns to optimize blade geometry for efficiency and durability.

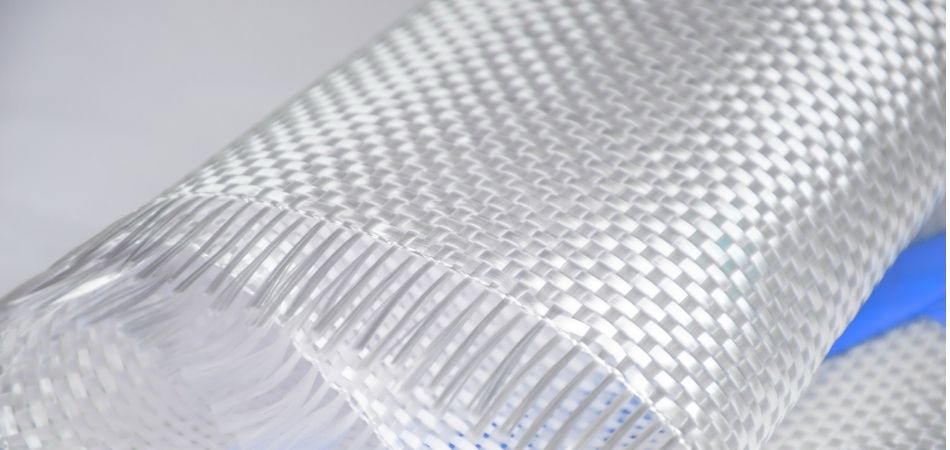

- Layering fiberglass and resin: Fiberglass mats or fabrics are placed into molds and infused with polymer resin. The precise vacuum forming process is sometimes used for certain components to ensure precision and reduce air pockets.

- Finishing Aspects: The resin hardens, bonding the fiberglass layers into a rigid composite. Blades are trimmed, sanded, and inspected using non-destructive testing methods.

Strict quality control is essential. Even minor defects can reduce performance or shorten blade lifespan. Every blade is tested before shipping to ensure it meets engineering standards.

Performance Advantages of Fiberglass Blades

Turbine performance and reliability are frequently affected by fiberglass blades.

- Energy Output Efficiency: At a lighter weight than metals, fiberglass blades are capable of rotating with less wind speed than their heavier counterparts. This leads to higher energy production from the same turbine.

- Durability Against Fatigue: Fiberglass can withstand the stress from millions of rotations without experiencing substantial wear or structural disintegration. Therefore, fiberglass blades provide long-term predictable performance over decades of use.

- Low Maintenance: Unlike metals, fiberglass blades have excellent resistance to corrosion and damage from the elements, leading to lower maintenance and downtime costs.

These advantages are particularly critical for offshore installations, where repair is costly and complex due to location and weather conditions. Fiberglass’s resistance to saltwater and extreme weather makes it essential for these applications.

Fiberglass and Environmental Sustainability

Renewable energy is inherently eco-friendly, but the materials used in turbine construction also matter. Fiberglass production requires energy and raw materials, which has raised concerns about sustainability.

Recent advancements aim to address this:

- Recyclable composites: Researchers are developing resins and fiberglass formulations that can be more easily recycled at the end of a blade’s life.

- Repurposing older blades: Some turbines are being transformed into infrastructure components such as bridges, sound barriers, and architectural elements, extending the material’s useful life.

- Eco-friendly resins: Bio-based and lower-emission resins reduce the environmental footprint of new blade production.

These innovations ensure that fiberglass not only supports renewable energy production but also aligns with broader sustainability goals.

The Role of Fiberglass in Offshore Wind Farms

Offshore wind energy is one of the fastest-growing segments of renewable energy. Offshore turbines are generally larger and generate more power, placing higher demands on materials. Fiberglass performs exceptionally well in these conditions because:

- It resists corrosion from saltwater.

- It tolerates extreme wind and temperature variations.

- It maintains structural integrity over long periods with minimal maintenance.

Some modern offshore blades combine fiberglass with small amounts of carbon fiber to enhance stiffness without significantly increasing cost. This hybrid approach allows for extremely long blades while keeping production feasible and safe.

Innovations in Fiberglass Technology

The future of wind energy depends on continuous improvements in blade materials. Fiberglass technology is evolving in multiple ways:

- Enhanced resin formulations: New resins improve strength, durability, and environmental performance.

- Automated manufacturing: Robotics and precision molding increase production speed and reduce defects.

- Smart blades: Embedded sensors monitor stress, vibration, and damage in real time, helping operators optimize maintenance and prolong blade lifespan.

These advancements ensure that fiberglass remains central to wind energy, even as turbines become larger and more powerful.

Fiberglass In Wind Turbines

Fiberglass is a critical material in renewable energy, enabling efficient, durable, and cost-effective wind turbine blades. Its combination of strength, light weight, and flexibility allows blades to capture more energy while withstanding harsh environmental conditions.

With the increasing use of wind energy, advancements in fiberglass materials, recycling, and production are expected to keep on helping both onshore and offshore wind energy production systems. It is important to understand the importance of fiberglass to appreciate the link between materials science and sustainable energy solutions. To get high-quality fiberglass services to satisfy the processing needs for wind energy production systems, contact BLG Fiberglass.