Main Services

Value-Added Services

Pattern Development (3D Digitization)

Mold Creation (CNC Machine Creates Master/Pattern)

Painting (Primer/Top)

Secondary Component Installation (PVC, Metal, Wood, and Rubber)

At BLG, our vacuum forming plastic process is designed to produce high-quality, durable components for a variety of industries. We work with materials such as PC, ABS, PVC, PS, PET, and more, using advanced blister forming machines

Our team also performs additional finishing steps, including folding, punching, and assembly, to deliver fully functional components.

Our optimized manufacturing workflow is built to support global industries with precision and scale. We deliver custom plastic forming and vacuum forming plastics to the USA, Canada, and Europe, specialized for automotive, medical, and commercial vehicle applications.

As a dedicated plastic supplier in North America, we don’t just provide raw materials – we provide engineering expertise. We design & construct the specific vacuum forming plastic components your industry demands.

We prioritize precision in every project to deliver incredible results. We make sure our clients receive durable vacuum forming plastic materials that satisfy industrial needs and long-term performance requirements.

We manufacture high-quality components for a diverse range of sectors, including Automotive, Marine, Wind Turbines, and Medical. We are equipped to handle the unique specifications & safety standards required by each global market.

Our end-to-end support includes pattern development, mold creation, painting, and secondary component installation. These custom plastic forming services allow us to deliver “plug-and-play” parts ready for immediate assembly.

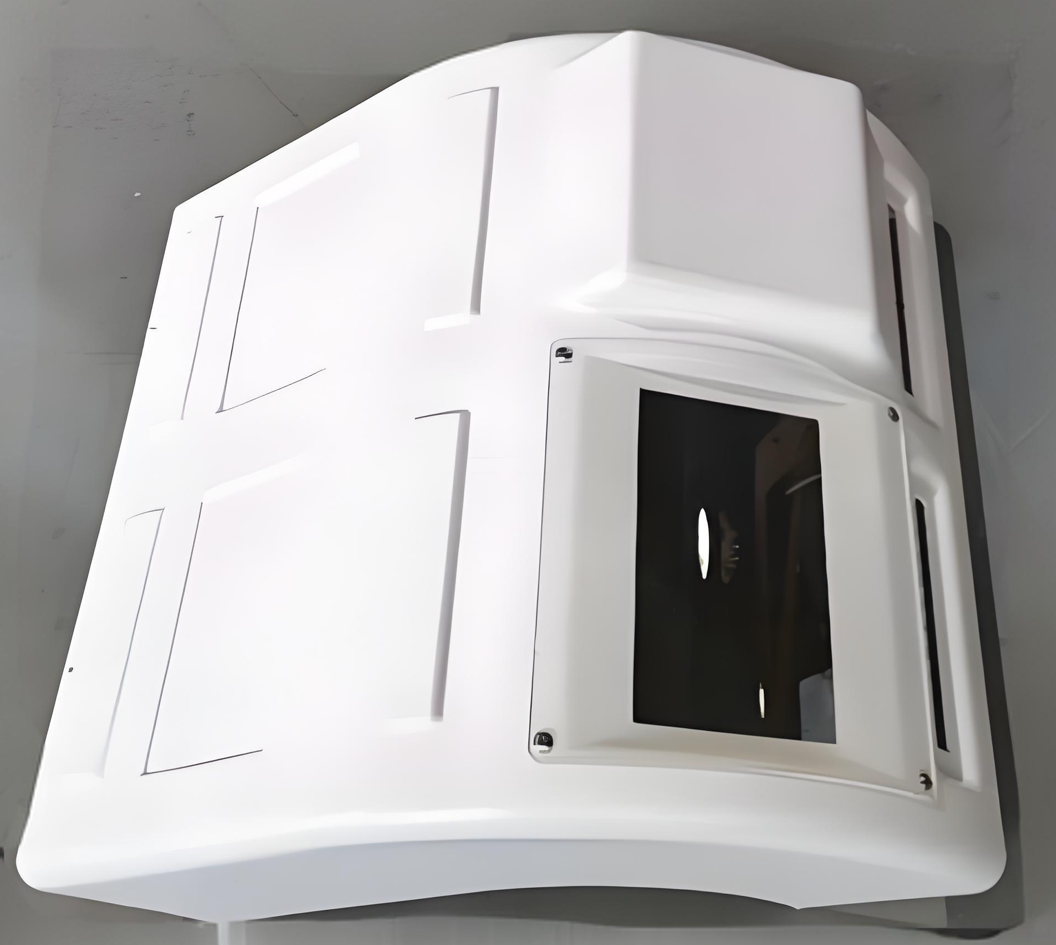

Our expertise includes creating components such as truck external parts, bumpers, internal panels, buses, tractors and trucks’ fenders, exterior trims, A-pillars, air deflectors, fan shrouds, windshield wiper housings (rain trays), battery boxes/covers, instrument panels, CT bodies, robot shells, and aircraft table boards using advanced vacuum forming plastics techniques.

Our composite materials for commercial vehicles Canada, the USA, and the EU are engineered for performance and longevity, offering benefits such as:

Excellent corrosion resistance; materials will not age

Lightweight yet strong structure

Low operational noise

High structural integrity with no deformation

Superior insulation performance

Beautiful, durable appearance with special surface treatment

Paint with strong adhesion that resists fading

When you choose BLG Fiberglass as your plastic supplier, you can count on every component being made to your exact specifications, with reliable, high-quality results you can trust across commercial vehicles and other industries.

Here’s what the process looks like from start to finish

The process begins with a flat thermoplastic sheet, typically made from materials such as ABS, PC, PVC, PS, or PET. The sheet is clamped into place and gradually heated until it reaches its forming temperature. At this point, the material becomes soft and pliable but does not melt.

Controlling the heating stage is critical – uneven heating can cause warping or weak spots in the final part.

Once the sheet is properly heated, it is lowered over a pre-made mold. A vacuum pump is then used to remove the air between the sheet and the mold, pulling the softened material tightly against every contour.

This ensures accurate replication of the mold’s details.

The precision of this step directly impacts the quality, strength, and dimensional accuracy of the final component.

After forming, the plastic must cool and harden to maintain its new shape.

Cooling is controlled to prevent shrinkage or deformation.

Once the part has cooled, it is carefully trimmed using CNC cutting or punching machines to remove excess material and achieve the final dimensions.

This trimming stage is where tolerances are refined to meet exact specifications.

Depending on the application, additional finishing steps are performed to prepare the component for use.

This may include:

Before components leave our facility, they undergo strict quality control checks. Dimensions, surface finish, and overall durability are verified against customer requirements and industry standards.

Only parts that meet specifications move forward for packaging and delivery.

This final step ensures customers receive reliable, high-performance components they can integrate with confidence.

While injection molding is for high volume, you can also see in which cases vacuum forming beats 3D printing for mid volume production.

| Feature | Vacuum Forming | Injection Molding |

|---|---|---|

| Tooling Cost | Lower upfront cost (affordable molds) | High tooling cost (expensive steel/aluminum molds) |

| Lead Time | Faster setup, ideal for prototypes and small runs | Longer setup, best for large production volumes |

| Part Detail | Moderate detail, good for large/simple parts | High precision, complex geometries possible |

| Production Volume | Best for low-to-medium quantities | Cost-effective at very high volumes |

| Material Use | Uses plastic sheets (less material waste) | Uses pellets, more control over material properties |

| Applications | Panels, covers, housings, trays | High-volume consumer goods, automotive parts |

| Feature | Vacuum Forming | Thermoforming |

|---|---|---|

| Definition | Uses vacuum pressure to pull heated plastic sheet over a mold. | General process of heating plastic sheets and shaping them with molds (includes vacuum forming). |

| Process Specificity | Subset of thermoforming focused on vacuum suction. | Umbrella term for several methods: vacuum forming, pressure forming, twin-sheet forming. |

| Detail Level | Moderate detail; good for simple or large parts. | Can achieve higher detail with pressure forming or twin-sheet methods. |

| Cost | Lower tooling cost, best for prototypes and short runs. | Cost varies—some methods more expensive, but more versatile. |

| Applications | Trays, enclosures, housings, packaging. | Packaging, medical trays, automotive panels, consumer products. |

We have been working with many different clients from a variety of industries. People come to us because we always deliver amazing final results that our clients love. If you need customized solutions for your components, our fiberglass and compound manufacturing company is the one you will want to call.

Our team manufactures components for businesses in many industries including:

The materials we vacuum from are mainly ABS, PC, PET, PS, PVC and specialty blends. Choose by requirement: ABS for good toughness and paintability; PC for impact resistance and clarity; PET for food-contact trays and stability; PS for low-cost rigid parts; PVC where chemical resistance is needed. If you tell us required strength, temperature range, and finish, we’ll recommend the optimal resin.

Typical finished wall thicknesses are 0.8-4.0 mm depending on initial sheet gauge and draw depth. Dimensional tolerances after trimming are typically ±0.5-1.5 mm for most features; tighter tolerances (±0.1–±0.3 mm) are achievable on short runs with CNC trimming and inspection – specify critical dimensions up front.

We can form sheets up to roughly 3.0m X 2.0m.

Vacuum forming dislikes undercuts and very deep draws. Draft angles (see next Q) and rounded transitions are essential. Deep draws may thin walls and need pressure forming or two-piece molds. If your design has undercuts, we’ll propose modification, reliefs, or a secondary assembly strategy.

Minimum recommended draft is 3°-5° on vertical walls. Internal radii should be at least 1-2× the final wall thickness to avoid thin spots and tearing. Sharp internal corners = weak/different wall thickness – avoid them.

Prefer locating bosses and inserts to be added post-forming. We can pre-punch or CNC-route holes; for threaded inserts we recommend heat-set or ultrasonic insertion after forming. Provide hole sizes and tolerance class early-we’ll advise on reinforcement or bushings if load-bearing.

Smooth, satin, pebble, leather grain and custom textures are available via textured molds or post coatings. We also offer paint finishes-automotive-grade primers and topcoats with controlled adhesion processes for long life. Learn how enclosures benefit from surface choices.

Not automatically. ABS and PC accept paint well with proper surface prep (flame or plasma treatment, primer). PVC and some proprietary blends may need specific primers. We test adhesion and provide adhesion certifications on request.

Yes. For sheet color we match to RAL or Pantone with a small color tolerance. For painted finishes we can do closer Pantone matches – provide a physical swatch for best results.

CNC trimming, punching, folding, heat-bending, drilling, painting, bonding, assembly, insert installation and custom packaging. We can deliver ready-to-install assemblies.

Typical lead times: prototype mold & 1–3 weeks for simple parts; complex molds 3–6 weeks. Production runs: 1–4 weeks depending on quantity, finishing, and assembly. We give a detailed schedule with every quote.

Part complexity and draw depth, mold material (MDF vs aluminium), sheet material and gauge, finish/painting, secondary operations, and quantity. Provide a BOM and annual volume estimate for the most accurate pricing.

Yes – but material and process choices must be validated. For medical/aerospace we use certified resins, controlled clean processes, and can provide material certifications (batch traceability). For food contact, we’ll supply FDA/EC compliant materials on request.

Visual inspection, dimensional checks (calipers/CMM on critical features), surface finish verification, adhesion tests for painted parts, and lot traceability. We can provide inspection reports and first-article inspection upon request.

Custom foam crating, palletizing, and protective film are standard. For exports to the USA/EU we handle export packaging and documentation. Tell us if parts need ESD protection, cleanroom packaging, or kitting.

For standard vacuum formed parts, MOQ depends on finish and tooling amortization: prototype runs can be as low as 1–10 parts, while production MOQ typically starts around 50–200 parts. Exact MOQ is quoted per job.

Yes – we will sign NDAs and control access to tooling and drawings. Request an NDA when sending sensitive designs.

We warrant parts against manufacturing defects and workmanship for a specified period (typically 12 months)-warranty terms are included in the quote and exclude damage from improper installation or abuse.

Yes. We recommend a prototype run to validate fit, finish and assembly – prototypes can be produced in final material or a close substitute, then revised quickly before tooling finalization.

BLG is a Canadian-based company founded in 2000 with headquarters in Toronto, Ontario. Our facilities in Shanghai and Jiangsu China comprise more than 50,000 square meters of office and manufacturing space. We specialize in manufacturing high-quality fiberglass products and providing bespoke solutions to meet our customers’ needs.

As the leading fiberglass and plastic supplier in Canada and other countries, we offer shipping to North America, South America, Europe, and Asia. Our primary fiberglass services include Fiberglass Reinforced Plastic (FRP), Resin Transfer Molding (RTM), and Sheet Molding Compound (SMC) and Forming Plastic. We have the expertise to provide customized fiberglass solutions to cater to our customers’ unique requirements.

Our company has developed strong working relationships with companies from so many industries because of our commitment to delivering high-quality components.

If you are looking to get a quote on your project or you need more information about our team and services, we encourage you to get in touch with us today. We look forward to hearing from you.