We see it all the time. A startup designs a brilliant new device enclosure or an automotive aftermarket part. They 3D print the first prototype, and it looks great. Then they print ten more for beta testing. Still good. But then comes the order for 500 units.

Suddenly, their “rapid” prototyping lab turns into a bottleneck. Printers are running 24/7, failure rates skyrocket, and the cost per unit stays stubbornly high. They aren’t ready for the $50,000 investment in injection molding, but they can’t survive the slow pace of additive manufacturing.

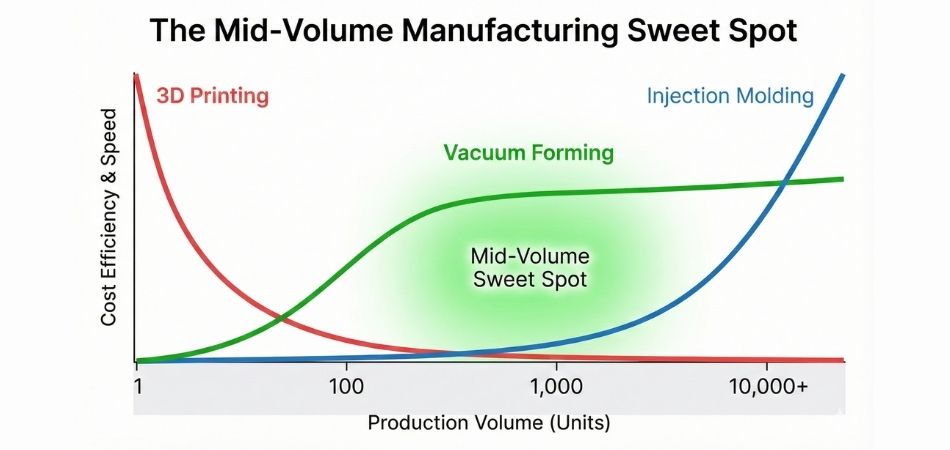

This is the “Mid-Volume Gap.” And the bridge across that gap isn’t more 3D printers. It is a custom vacuum forming production.

In this guide, we will break down exactly why switching to vacuum forming mid-volume runs is the smartest financial and engineering decision you can make for your growing business.

The Economics of Vacuum Forming Mid-Volume Runs

The biggest myth in manufacturing is that 3D printing is “cheaper” because there is no tooling cost. This is only true if you are making less than 50 parts. Once you cross into mid volume territory (50 to 5,000 units), the math changes dramatically. You stop paying for the tool and start paying for the time. With 3D printing, you are paying a premium for every single hour that printer nozzle is moving.

Vacuum forming flips this equation. You pay a moderate upfront cost for a mold (often made of aluminum or composite), but your unit cost drops through the floor. The “Crossover Point” where vacuum forming becomes cheaper than 3D printing is often surprisingly low, usually around 50-100 units. If you are planning to sell 500 units, sticking with 3D printing is literally burning money.

Key Financial Takeaways for Production Managers

- Tooling Amortization: A $2,500 vacuum form tool spread over 500 parts adds only $5 to the part cost.

- Material Cost: Thermoplastic sheets cost significantly less per pound than 3D printing filament or resin.

- Hidden Costs: 3D printing requires manual support removal (labor cost). Vacuum forming parts come off the machine ready for simple trimming.

- Risk Reduction: Vacuum forming molds are durable and can last for thousands of cycles, unlike 3D printers which require constant maintenance.

| Cost Factor | 3D Printing (FDM/SLA) | Vacuum Forming Mid Volume |

|---|---|---|

| Setup / Tooling | $0 (Zero Upfront) | $2,000 – $5,000 (One-time) |

| Unit Cost (Material + Labor) | High ($25.00+ typical) | Low ($4.00 – $8.00 typical) |

| Labor for Finishing | High (Sanding/Support Removal) | Low (CNC Trimming) |

| Total Cost for 500 Units | $12,500+ | $6,500 (Includes Tooling!) |

Speed and Lead Times in Mid-Volume Production

Time is the one resource you cannot buy back. In the world of 3D printing, speed is measured in hours per part. A large, complex housing for a medical device might take 15 to 20 hours to print. If you need 500 of them, you either need a massive farm of printers or you need to wait months for your order to be fulfilled.

Vacuum forming mid-volume orders changes the metric from “hours per part” to “minutes per cycle.” Once our machines are heated and running, we can form a large, complex part every 3 to 5 minutes. We can produce in a single shift what would take a 3D print farm weeks to complete. This speed allows you to get your product to market faster and restock inventory immediately when demand spikes.

Why Vacuum Forming Wins the Race

- Parallel Processing: We can often form multiple small parts in a single cycle using a “multi-up” mold.

- No “Print Failures”: We don’t have to worry about a print failing at 99% completion. The process is robust and repeatable.

- Rapid Tooling Options: For urgent projects, we can even 3D print the mold itself or machine it from high-density tooling board to start production in days, not weeks.

- Consistent Throughput: Our industrial machines run continuously without the need for constant recalibration.

| Production Metric | 3D Print Farm (10 Machines) | Single Vacuum Forming Machine |

|---|---|---|

| Cycle Time per Part | 10 Hours | 3 Minutes |

| Daily Output (8hr shift) | ~8 Parts (Total) | ~150 Parts (Total) |

| Scalability | Linear (Must buy more printers) | Geometric (Just run machine longer) |

| Failure Rate | High (Clogs, Adhesion issues) | Low (<1% Reject Rate) |

Isotropic Durability vs. Anisotropic Weakness

This is where the engineering reality sets in. 3D printed parts (especially FDM) are anisotropic. This means they are built in layers, and the bond between those layers (the Z-axis) is inherently weaker than the rest of the part. If you drop a 3D printed enclosure, it will almost always snap along a layer line. It is like building a wall out of Lego bricks without glue.

Vacuum forming utilizes extruded thermoplastic sheets. These sheets have isotropic properties, meaning the molecular chains are continuous and uniform in every direction. When we heat and stretch the sheet, we maintain that structural integrity. A vacuum-formed part made from Polycarbonate or ABS is virtually shatterproof and offers superior chemical resistance compared to printed parts. For a deeper dive into material properties, you can reference standard data sheets from sources like MatWeb.

Engineering Advantages of Formed Sheets

- Impact Resistance: Vacuum-formed parts absorb shock rather than shattering.

- Watertight Integrity: Because there are no layers, there are no microscopic gaps for water or dust to ingress.

- Chemical Resistance: Materials like HDPE offer innate resistance to harsh chemicals that would dissolve 3D printing resins.

- Thermal Stability: We can use high-temperature plastics that would be impossible or incredibly expensive to 3D print.

| Property | FDM 3D Print (ABS) | Vacuum Formed Sheet (ABS) |

|---|---|---|

| Structure | Layered (Weak Z-axis) | Solid / Continuous |

| Waterproof? | No (Micro-porous) | Yes (100% Sealed) |

| Impact Strength | Low (Brittle) | High (Ductile) |

| UV Stability | Poor (Unless painted) | Excellent (UV-capped sheets available) |

Aesthetics and Surface Finish in Mid-Volume Production

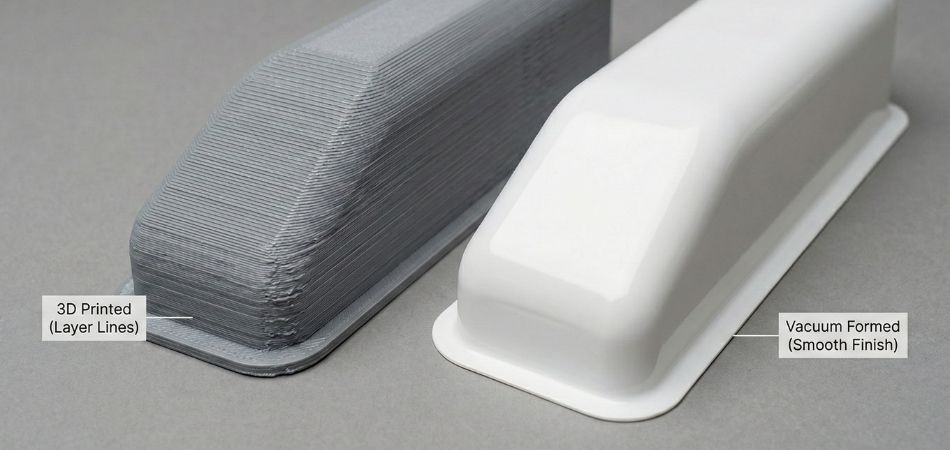

If you are selling a commercial product, “looks” matter. A 3D printed part screams “prototype” due to the visible layer lines and stair-stepping effect on curved surfaces. To make a printed part look professional, you have to spend hours sanding, filling, priming, and painting it. This manual labor destroys your profit margins.

With vacuum forming mid-volume production, the surface finish is determined by the sheet and the mold. We can produce parts with a perfect Class-A high gloss finish, a soft-touch matte finish, or a rugged “haircell” texture that hides scratches. The part comes off the machine looking like a finished product, not a science project. You can choose pre-colored sheets to match your brand colors exactly, eliminating the need for paint entirely.

Achieving the “Factory Look”

- Texture Matching: We can mold logos, text, and specific grain patterns directly into the plastic.

- No Layer Lines: Curves are smooth and organic, not pixelated steps.

- Color Consistency: The color is embedded throughout the plastic sheet, so scratches won’t reveal a different color underneath.

- Cleanability: Smooth vacuum-formed surfaces are easy to sanitize, making them ideal for medical use.

| Feature | 3D Printing | Vacuum Forming |

|---|---|---|

| Surface Texture | Rough / Layered | Smooth, Textured, or Gloss |

| Post-Processing | Heavy (Sanding, Painting) | Minimal (Trimming only) |

| Color Options | Limited filaments | Thousands of custom sheet colors |

| Consistency | Variable between printers | Identical part to part |

Moving Beyond the Prototype With Vacuum Forming

3D printing is an incredible technology. We love it for proof-of-concept models and one-off custom jigs. But when your business grows and you need to deliver 50, 500, or 5,000 parts, relying on it is a strategic error.

Vacuum forming mid-volume production offers you the sweet spot of manufacturing. You get the speed and durability of mass production with tooling costs that won’t bankrupt your startup. You get parts that are stronger, look better, and cost less.

Don’t let the “Mid-Volume Gap” slow down your growth. If you are ready to upgrade your manufacturing strategy, contact the engineering team at BLG Fiberglass today. Let us look at your CAD files and show you exactly how much time and money you can save.