The terms glass fiber and fiberglass are often used interchangeably with regard to materials in construction, manufacturing, or industrial applications. While the two are related materials, they differ in purpose and characteristics. Knowing the difference will help you make smarter decisions for your projects.

What is Glass Fiber?

Glass fiber is manufactured from very fine strands of glass, usually only a few microns in diameter. These fibers are lightweight yet incredibly strong, making them very suitable for reinforcement purposes in other materials. The heat and corrosion resistance, as well as resistance to chemical exposure, makes such fibers invaluable in those industries where durability and performance are called for.

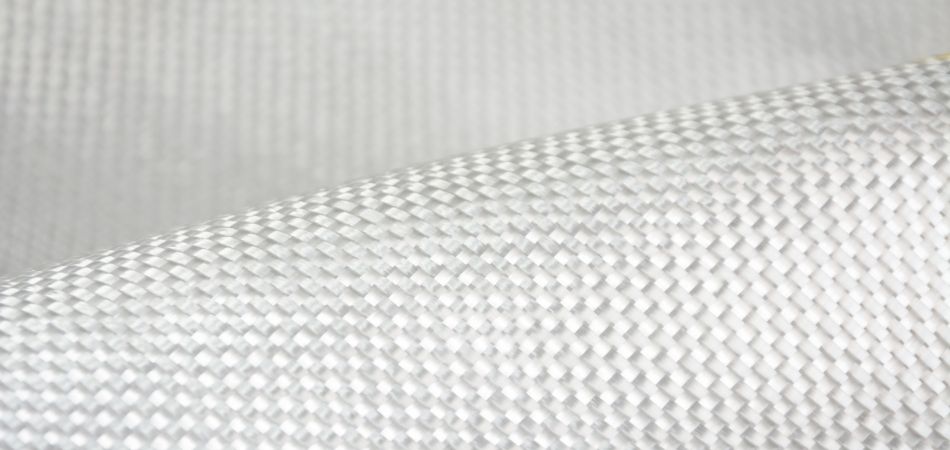

Glass fiber comes in several forms:

- Chopped strands: Short fibers used in molded composites.

- Woven mats and fabrics: Used in lamination and reinforcement.

- Rovings: Bundled fibers often used in pultrusion processes.

This flexibility in form allows glass fiber to be integrated into a variety of applications, from insulation and textiles to reinforcement in composite structures.

What is Fiberglass?

Fiberglass, on the other hand, is a finished composite material made by combining glass fibers with a resin, such as polyester, epoxy, or vinyl ester. This combination creates a material that is not only strong and lightweight but also versatile and moldable.

Fiberglass is commonly used in:

- Automotive components like car panels and hoods.

- Marine applications such as boat hulls and canoes.

- Industrial items like pipes, tanks, and storage containers.

- Construction materials including roofing panels and decorative elements.

In essence, fiberglass is the final product, while glass fiber is the raw material that provides the strength and reinforcement.

Key Differences Between Glass Fiber and Fiberglass

| Feature | Glass Fiber | Fiberglass |

| Composition | Pure glass fibers | Glass fibers + resin |

| Strength | High tensile strength | Strong but depends on resin type |

| Form | Mats, fabrics, strands | Sheets, molded products |

| Flexibility | Very flexible | Less flexible due to resin binding |

| Applications | Reinforcement, insulation, textiles | Boats, automotive parts, panels, pipes |

Practical Implications: Why the Difference Matters

Choosing between glass fiber and fiberglass depends on your project needs:

- Glass fiber is perfect when raw reinforcement is needed for composites or when flexibility is key.

- Fiberglass works best when a finished, rigid, and durable product is required.

For example, in vacuum forming processes, fiberglass sheets can be molded into precise shapes while retaining strength and durability. This makes fiberglass ideal for applications where complex shapes and consistent performance are critical, such as automotive dashboards or industrial panels.

Advantages of Each Material

Glass Fiber Advantages:

- Lightweight and easy to handle

- High tensile strength

- Resistant to heat and chemicals

- Flexible and versatile for custom applications

Fiberglass Advantages:

- Durable and impact-resistant

- Moldable into complex shapes

- Low maintenance and corrosion-resistant

- Cost-effective for large-scale production

Choosing the Right Material for Your Project

When deciding which material to use, consider the end goal:

- Structural Reinforcement: Use glass fiber for raw strength in composites.

- Finished Products: Use fiberglass for durable, molded items that can withstand environmental stress.

- Specialized Processes: If you’re using techniques like vacuum forming, fiberglass offers the rigidity and formability used for a variety of high-precision applications.

Now You Know…

While glass fiber and fiberglass are interrelated, the differences fundamentally lie in composition and application: glass fiber provides the backbone, with raw strength and flexibility, while fiberglass is the finished material employed in everything from automotive to marine and industrial manufacturing. Being able to understand the differences enables you to select the appropriate material for your project and enhances product performance while taking advantage of processes such as vacuum forming for strong, precise, and reliable results.